Product Description

Small Pitch Roller Chains

Type: PC 35, PC 40, PC50, PC60

Materials: POM+ stainless steel

Pitch: 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm

Color: White

We are manufacturer professionally in plastic top chains, stainless steel top chains, and other conveyor components. We have abtained the quality certificate of ISO 9001: 2000, and our products have been sold to Europe, Middle East, America and many other coutries and regions.

| type | PC 35, PC 40, PC50, PC60 |

| Materials | POM+ stainless steel |

| Pitch | 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm |

Small Pitch Roller Chains

Type: PC 35, PC 40, PC50, PC60

Materials: POM+ stainless steel

Pitch: 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm

Color: White

Advantages: short pitch, low noise, light weight,

corrosion resistance, diamagnetic.

Plasic roller chains can be widely use for eletronic, food,medicine, chemical industry etc.

We are manufacturer professionally in plastic top chains, stainless steel top chains, and other conveyor components. We have abtained the quality certificate of ISO 9001: 2000, and our products have been sold to Europe, Middle East, America and many other coutries and regions.

Our products application:

Packaging and conveying industry

Beverage bottling and handling industry

Food and meat processing industry

Chemical industry

Pharmaceuticals industry

Automobile industry

Electrical and electronics industry

Textile industry

Light engineering industry

| Material: | Plastic |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | No |

| Chain Size: | 12.7mm |

| Feature: | Wear Resistant |

| Advantage: | Corrosion Resistance |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do roller chains handle high humidity environments?

Roller chains are designed to withstand a wide range of environmental conditions, including high humidity environments. Here’s a detailed answer to the question:

1. Corrosion Resistance: Roller chains can be manufactured using corrosion-resistant materials such as stainless steel or with special coatings that provide protection against rust and corrosion. These features help the chain withstand the effects of high humidity, which can cause moisture to come into contact with the chain surface.

2. Lubrication: Proper lubrication is essential in high humidity environments to prevent moisture from penetrating the chain and causing corrosion. Lubricants with water-resistant properties or specifically designed for humid conditions can be used to provide a protective barrier on the chain’s surfaces, minimizing the impact of moisture.

3. Seal Options: Some roller chains come with additional sealing elements, such as O-rings or X-rings, that provide an extra layer of protection against moisture ingress. These seals help keep the lubrication inside the chain and prevent contaminants from entering, reducing the risk of corrosion.

4. Maintenance Practices: Regular maintenance is crucial in high humidity environments to ensure the longevity of roller chains. Cleaning the chain to remove any accumulated moisture, dirt, or debris and applying appropriate lubrication at recommended intervals help mitigate the effects of humidity on the chain’s performance and lifespan.

5. Proper Storage: When not in use, roller chains should be stored in a dry and controlled environment to prevent prolonged exposure to high humidity. Using appropriate storage methods, such as sealed containers or dehumidified storage areas, can help preserve the chain’s integrity and minimize the risk of corrosion.

By considering these factors and implementing proper maintenance practices, roller chains can effectively handle high humidity environments, ensuring their reliable performance and extended lifespan.

Can roller chains be used for power transmission in construction equipment?

Roller chains can indeed be used for power transmission in construction equipment. Here’s a detailed answer to the question:

Construction equipment often requires a reliable and robust power transmission system to handle heavy loads and operate in demanding environments. Roller chains offer several advantages that make them well-suited for power transmission in construction equipment:

1. High Strength: Roller chains are designed to withstand high tensile and impact loads, making them suitable for the heavy-duty requirements of construction equipment. They are capable of transmitting substantial power without deformation or failure.

2. Durability: Construction sites can expose equipment to harsh conditions such as dust, debris, and vibrations. Roller chains are built to be durable and resistant to these challenging environments. They are constructed from high-quality materials and undergo heat treatment processes to enhance their strength and wear resistance.

3. Versatility: Roller chains can be used in various construction equipment applications, including excavators, loaders, bulldozers, cranes, and concrete mixers. They can efficiently transmit power from the engine to different components such as wheels, tracks, and attachments, allowing the equipment to perform a wide range of tasks.

4. Cost-Effectiveness: Roller chains offer a cost-effective solution for power transmission in construction equipment. They have a relatively low initial cost compared to alternative systems, and their durability and long service life contribute to lower maintenance and replacement costs over time.

5. Easy Installation and Maintenance: Roller chains are easy to install and maintain, requiring regular lubrication and periodic inspection for wear and proper tension. Maintenance tasks can be performed on-site, reducing downtime and increasing equipment availability.

It’s important to note that proper chain selection, sizing, and maintenance are crucial for ensuring optimal performance and longevity in construction equipment applications. Following the manufacturer’s guidelines and recommendations for chain installation, lubrication, and tensioning is essential to maximize the efficiency and reliability of the power transmission system.

What are the key components of a roller chain?

A roller chain consists of several key components that work together to facilitate power transmission. Here’s a detailed answer to the question:

1. Inner and Outer Plates: The inner and outer plates are flat metal plates that form the sides of the roller chain. They provide support and protection to the other components and help maintain the proper spacing between the rollers.

2. Rollers: The rollers are cylindrical components that are positioned between the inner and outer plates. They are responsible for engaging with the sprockets and transmitting power. The rollers rotate freely on the bushings and reduce friction during operation.

3. Bushings: The bushings are cylindrical sleeves that fit inside the rollers. They provide a low-friction surface for the rollers to rotate on and help reduce wear and extend the life of the chain.

4. Pins: The pins are cylindrical metal rods that connect the inner and outer plates. They pass through the bushings and hold the chain together. The pins are press-fitted into the plates and provide a pivot point for the rollers.

5. Link Plates: The link plates are the connecting elements between adjacent chain links. They are the plates that hold the pins in place and provide structural integrity to the chain.

6. Master Link or Connecting Link: The master link, also known as the connecting link, is a special link that allows for easy installation and removal of the roller chain. It typically has a removable pin or clip that enables the chain to be opened and closed without the need for special tools.

These components work together to form a continuous loop that engages with the sprockets and transfers power from one shaft to another. The precise design and construction of these components contribute to the overall strength, durability, and efficiency of the roller chain.

editor by CX 2023-09-15

China Wholesale New Product Professional Machine Made 925 Sterling Silver Necklace Chains double roller chain sprockets

Solution Description

women’s 925 silver jewelry chain metal pendant chain

| Product NO. | CN571 |

| Top quality level | Initial class, rustless,non-corrosion,no-fading |

| Components | 925 silver |

| Craftwork | Minimize tube,CNC Engraved,Stone placing,Large polished , sandblasting, Matt ,Laser,Plating, Top quality examine,Bundle |

| Surface area | Polish or Matte |

| Plating coloration | As picture or 18K gold or rose gold or black |

| Dimension | As your request . |

| Tolerance | ±0.05mm , even can make the tolerance inside of ±0.02mm |

| MOQ | 20-30pcs for each measurement for each product |

| Logo | Can laser print your emblem in accordance to your request |

| Delivery time | Sample Time 3-7 organization times Bulk get 25-30 organization days after confirmation |

| Payment terms | T/T ,Western Union , Paypal. fifty% deposit before creation, the balance fifty% prior to transport |

| Shipping | DHL ,UPS ,EMS,Fedex, TNT, and many others. three-7 times |

| Packaging | Internal packing :1pcs/opp bag 50pcs/huge opp bag, Outer packing :five hundred-1000pcs/carton |

| OEM/ODM | Recognized |

| Sample | Sending samples very first for testing high quality is offered Sample cost is refundable |

| Promise interval | one-2years |

| Jewelry Exhibition | HongKong Jewellery reasonable and others |

| Manufacturing facility Check out | Welcome |

Aspiration Only Jewelry Co., Ltd

Expert substantial course jewelry & ring manufacturing unit More than 10 many years historical past .

Have created secure business spouse relations with several famous European jewellery brands for 3 years

1.Organization Procedure

two.Craft procedure

3.Best Good quality

one).High high quality from uncooked material,Eco-helpful and sturdy

2)Superb Craft,specialists below With twenty many years of jewellery work experience

three)Rigorous high quality examine.Each and every jewellery will go via 2 times inspection 1 bye 1.

A .Sample control, we will not begin to make the products until your affirm the sample.

B .All you items will be manufactured by competent labor.

C .We will create 2~5% much more merchandise to substitute the Defective Goods.

D .The packing will be shock proof ,damp evidence and sealed.

four.Safety and quickly Shipping

Our organization cooperated with some famous transport organizations,they supply more affordable shipping and delivery cost and quicker transport time ,give our parcel protection excursion.

A variety of of Delivery way ,could ship as your request, generally transport date is about 3-7days.

five.Right after Sales:

1).We are extremely happy that customer give us some suggestion for price and merchandise.

two).If any query, remember to enable us know it in the 1st by E mail or Phone. We can deal with them for you in time.

3). We will send several new styles in each week to our old buyers

4).If the goods are eroded right after you obtain, make sure you permit us know so that we can compensate it to you in time.

six.Contact

Desire Only Jewelry Co., Ltd

Web site: dreamonlyjewelry

|

US $1.5-3.95 / Piece | |

50 Pieces (Min. Order) |

###

| Material: | 925 Sterling Silver |

|---|---|

| Plating: | Rhodium |

| Pendant Shape: | Round |

| Suitable for: | Female |

| Style: | Fashion |

| Usage: | Decoration, Health, Wedding Engagement or Aniversary or Gift |

###

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Item NO. | CN025 |

| Quality level | First class, rustless,non-corrosion,no-fading |

| Materials | 925 silver |

| Craftwork | Cut tube,CNC Engraved,Stone setting,High polished , sandblasting, Matt ,Laser,Plating, Quality check,Package |

| Surface | Polish or Matte |

| Plating color | As photo or 18K gold or rose gold or black |

| Size | As your request . |

| Tolerance | ±0.05mm , even can make the tolerance within ±0.02mm ; |

| MOQ | 20-30pcs per size per model |

| Logo | Can laser print your logo according to your request |

| Delivery time | Sample Time 3-7 business days Bulk order 25-30 business days after confirmation |

| Payment terms | T/T ,Western Union , Paypal. 50% deposit before production, the balance 50% before shipping |

| Shipping | DHL ,UPS ,EMS,Fedex, TNT, etc. 3-7 days |

| Packaging | Inner packing :1pcs/opp bag 50pcs/big opp bag, Outer packing :500-1000pcs/carton |

| OEM/ODM | Accepted |

| Sample | Sending samples first for testing quality is available Sample cost is refundable |

| Guarantee period | 1-2years |

| Jewelry Exhibition | HongKong Jewelry fair and others |

| Factory Visit | Welcome |

|

US $1.5-3.95 / Piece | |

50 Pieces (Min. Order) |

###

| Material: | 925 Sterling Silver |

|---|---|

| Plating: | Rhodium |

| Pendant Shape: | Round |

| Suitable for: | Female |

| Style: | Fashion |

| Usage: | Decoration, Health, Wedding Engagement or Aniversary or Gift |

###

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Item NO. | CN025 |

| Quality level | First class, rustless,non-corrosion,no-fading |

| Materials | 925 silver |

| Craftwork | Cut tube,CNC Engraved,Stone setting,High polished , sandblasting, Matt ,Laser,Plating, Quality check,Package |

| Surface | Polish or Matte |

| Plating color | As photo or 18K gold or rose gold or black |

| Size | As your request . |

| Tolerance | ±0.05mm , even can make the tolerance within ±0.02mm ; |

| MOQ | 20-30pcs per size per model |

| Logo | Can laser print your logo according to your request |

| Delivery time | Sample Time 3-7 business days Bulk order 25-30 business days after confirmation |

| Payment terms | T/T ,Western Union , Paypal. 50% deposit before production, the balance 50% before shipping |

| Shipping | DHL ,UPS ,EMS,Fedex, TNT, etc. 3-7 days |

| Packaging | Inner packing :1pcs/opp bag 50pcs/big opp bag, Outer packing :500-1000pcs/carton |

| OEM/ODM | Accepted |

| Sample | Sending samples first for testing quality is available Sample cost is refundable |

| Guarantee period | 1-2years |

| Jewelry Exhibition | HongKong Jewelry fair and others |

| Factory Visit | Welcome |

What to look for in a roller chain

There are many different factors to consider when purchasing a roller chain. One of the most important factors is tensile strength, which represents the force required to break the chain. Roller chains are available in three different tensile strengths: minimum, average and ultimate. Each strength reflects a different limit to the load the chain can handle. However, these limits are not always equal and you should be aware of the differences between roller chains.

Canonical chain

Most roller chains have standard sizes printed on the side panels. This is usually “40” or “C2080H”, but can also be the letter “B”. If the chain is old, it will need to be cleaned to see its size. You can find the size on the standard roller chain size chart, but not everyone is marked. To determine the size, measure the diameter and pitch of the chain, then compare the results to the chart to see what size you need.

Heavy-duty roller chains are available with heat-treated pins, side plates, and rollers. In addition to being heat treated, they are also factory pre-stretched, which reduces wear on these parts. If properly maintained, they can last for years, reducing the risk of failure or corrosion. Depending on the application, standard roller chains are available in different sizes. It can be purchased separately. There are several options to choose from, depending on the size and strength of the application.

PEER roller chains contain solid rollers to reduce shock loads on the sprocket teeth. Heat treating and preloading all components of the PEER chain helps minimize initial elongation. Hot-dip lubrication ensures complete lubrication of all chain components, extending their life and reducing maintenance costs. For heavy-duty applications, ASME/ANSI-B29.1 chain is a good choice.

Standard roller chains are made of steel or alloy steel. However, it can be made of other materials such as stainless steel. In addition to steel, stainless steel is often used in food processing machinery where chain lubrication is an issue. Brass and nylon are also sometimes used. However, they are not that popular. Therefore, you should always check with your supplier before purchasing. By comparing the tensile strength of two different chains and making an informed decision, you can get the best price and service.

Chain without bushing

Bushless roller chains have advantages over conventional roller chains. Unlike conventional chains, bushless chains have extensive lateral flexibility, which increases the chain’s lubrication flow. The inner plates of bushless chains have protruding shoulders so the oil can flow through them more easily and efficiently. This is an important characteristic of a smooth-running chain. Additionally, bushless chains may have improved shifting performance.

The strength of a bushingless roller chain is measured in terms of tensile strength and fatigue strength. The former measures the load a chain can withstand before breaking. Fatigue strength is equally important, and factors that affect fatigue strength include the steel used to make the chain components, the pitch hole fabrication, the type of shot peening on the chain, and the design and thickness of the chain. For example, if the chain is too thin, it may not be enough for heavy-duty applications.

Like traditional roller chains, bushingless roller chains have two different types of links. The inner link has two inner plates connected by pins, while the outer chain has two outer plates held together by bushings. A bushingless roller chain is similar to a traditional chain, except it eliminates a step in the assembly process by stamping the tube into the inner plate. So if you want a smoother ride, a bushingless roller chain is a better choice.

There are two different sizes of bushingless roller chains. One size is designed for use with standard single-strand chains, while the other size is designed for use with double-strand or triple-strand chains. Bushless chains are generally shorter than conventional chains, so they can fit in tighter spaces. Bushless chains are made of the highest quality materials. These chain attachments are case hardened for optimum strength and durability.

Mute chain

The silent roller chain has a smooth, low-noise drive. They are made of stacked rows of flat chainplates with a gear-like profile that meshes with the sprocket teeth. Each chainplate is attached to a corresponding sprocket, which also allows the chain to bend. While these basic components are the same for every silent roller chain, there are many variations that allow them to be used in a variety of applications.

The most popular high-speed transmission, silent chains feature gear-like sprockets. They can be made from single or multiple strands of material. Single-strand chains are less expensive than multi-strand chains, but they tend to wear out faster if not lubricated. Single-strand roller chains can be used for years without lubrication, but for your application, wide silent chains are still worth considering.

The design and construction of silent chains make them ideal for conveying a wide variety of products. They have flat, heat-resistant surfaces. They are also durable and non-slip. They are available in a variety of pitch sizes, widths, and mounting styles. Whether you need chains for general purpose conveyors or glass bottle transport applications, we have you covered. Ask about the benefits of silent roller chain conveyors.

Inverted tooth chains are another option for quieter chains. These chains are designed to reduce noise from engine-related friction. Silent chains are more common, and manufacturers have fallen in love with them. A silent chain consists of several links connected to the sprocket teeth. Teeth rotate to reduce noise, vibration, and chord action. These are the main reasons why silent chains are so popular.

ANSI chain pitch

To measure your bike’s chain pitch, you can use a caliper. This measurement is taken from the center of the rolling pin to the center of the next rolling pin. Chains come in many sizes, but ANSI is the most common chain standard in the United States. A caliper is handy if you’re not sure which size to buy, as it allows you to check for worn sprockets.

Chains that meet ANSI standards will be characterized by a certain pitch. This measurement is based on the width and spacing of the roll. The spacing is usually greater than the width. The standard number will be the right number for the width of the chain or the left number for the rollers. The number on the left indicates whether the chain is lightweight or heavyweight. Heavyweight chains are designated by the suffix “H”.

Common chain sizes are based on ANSI chain pitch. Pitch is the minimum distance between bushing and sprocket. The smaller the chain pitch, the greater the total distance between the two points. This means the chain will last longer. However, if you are buying a chain for a specific application, you should check the pitch carefully as it can affect the performance of the chain.

Roller chain wear measurement

The purpose of roller chain wear measurement is to prevent breakage by monitoring the strain on the chain. There are several ways to measure roller chain wear. The first is to remove the chain from its working position and measure the distance from the sprocket to its measuring end. Another way is to measure the pitch of the chain or the distance between two pins. This method is superior to other methods because it is convenient and accurate.

When measuring the wear of a roller chain, it is important to note that the elements of the chain will gradually deform. About 3.75% of the total wear will be on the pins and the rest will be on the internal links. These wear measurements will vary based on the nominal pitch of the chain and the amount of friction the chain is experiencing. Proper lubrication between pins and bushings, load and frequency of articulation all affect wear rates.

It is important to measure the amount of wear on the roller chain to avoid excessive machine failures. The longer the chain runs, the more wear it will wear. Although the length of the chain should be less than the center distance, the excessive load will cause premature wear. Therefore, lubrication is essential. Additionally, the sag of the chain should not exceed 2% to 4% of its center-to-center distance. Finally, check for unusual noise or visible defects. A common cause of excessive roller chain wear is the size of the load. Every chain manufacturer sets a maximum workload for its product.

There are several ways to measure roller chain wear. If using a high-speed drive, it should have at least 11 teeth, and a medium-speed drive should have at least 25 teeth. Also, be sure to check the length of the chain, even if you should. The same goes for the pin diameter, which should be the same or different pitch as the roller chain.

editor by czh 2023-01-25

China CNC Nylon Cable Machine Drag Tray Chain Carrier Cable Chain bush chain for sale

Solution Description

Merchandise Description

cnc nylon cable machine drag tray chain carrier

Information parameter

| Variety | Inside Diameter | Outside Diameter | Bending radius | Non-help |

| LX45.1 | forty five*fifty | 66*82 | one hundred.a hundred twenty five.a hundred and fifty.200 | three.five |

| LX45.2 | 45*sixty | 66*ninety three | a hundred.125.a hundred and fifty.two hundred | three.five |

| LX45.3 | 45*seventy five | sixty six*108 | 100.one hundred twenty five.150.200 | 3.5 |

| LX45.4 | 45*100 | 66*133 | a hundred.a hundred twenty five.a hundred and fifty.200 | three.5 |

| LX45.five | 45*a hundred twenty five | 66*158 | a hundred.a hundred twenty five.a hundred and fifty.200 | 3.five |

| LX45.six | 45*150 | 66*183 | 100.125.one hundred fifty.200 | three.five |

| LX45.7 | forty five*one hundred seventy five | 66*208 | one hundred.125.one hundred fifty.200 | 3.five |

| LX45.eight | forty five*two hundred | 66*233 | one hundred.125.150.200 | 3.5 |

Packaging & Shipping and delivery

FAQ

We are company of cheerleading rolling mat situated in HangZhou metropolis . and we have exported to numerous nations these kinds of as Usa, Canada ,Austrilia , United kingdom , Chile , New Zealand ,Japan ect.

Any concern , pls really feel totally free to get in touch with us .

| Logo Printing: | Without Logo Printing |

|---|---|

| Size: | Small |

| Customized: | Customized |

| Type: | Cutting Tool |

| Material: | Plastic |

| Certification: | ISO 9001:2008, ISO 9001:2000, GS, CE |

###

| Customization: |

Available

|

|---|

###

| Type | Inside Diameter | Outside Diameter | Bending radius | Non-support |

| LX45.1 | 45*50 | 66*82 | 100.125.150.200 | 3.5 |

| LX45.2 | 45*60 | 66*93 | 100.125.150.200 | 3.5 |

| LX45.3 | 45*75 | 66*108 | 100.125.150.200 | 3.5 |

| LX45.4 | 45*100 | 66*133 | 100.125.150.200 | 3.5 |

| LX45.5 | 45*125 | 66*158 | 100.125.150.200 | 3.5 |

| LX45.6 | 45*150 | 66*183 | 100.125.150.200 | 3.5 |

| LX45.7 | 45*175 | 66*208 | 100.125.150.200 | 3.5 |

| LX45.8 | 45*200 | 66*233 | 100.125.150.200 | 3.5 |

| Logo Printing: | Without Logo Printing |

|---|---|

| Size: | Small |

| Customized: | Customized |

| Type: | Cutting Tool |

| Material: | Plastic |

| Certification: | ISO 9001:2008, ISO 9001:2000, GS, CE |

###

| Customization: |

Available

|

|---|

###

| Type | Inside Diameter | Outside Diameter | Bending radius | Non-support |

| LX45.1 | 45*50 | 66*82 | 100.125.150.200 | 3.5 |

| LX45.2 | 45*60 | 66*93 | 100.125.150.200 | 3.5 |

| LX45.3 | 45*75 | 66*108 | 100.125.150.200 | 3.5 |

| LX45.4 | 45*100 | 66*133 | 100.125.150.200 | 3.5 |

| LX45.5 | 45*125 | 66*158 | 100.125.150.200 | 3.5 |

| LX45.6 | 45*150 | 66*183 | 100.125.150.200 | 3.5 |

| LX45.7 | 45*175 | 66*208 | 100.125.150.200 | 3.5 |

| LX45.8 | 45*200 | 66*233 | 100.125.150.200 | 3.5 |

Advantages and disadvantages of roller chains

If you need to lift heavy objects, you should know how to use a roller chain. Its simple design and simplicity make it ideal for a wide range of applications. This article will discuss the advantages and different types of applications of roller chains. After reading this article, you will be able to choose the type of roller chain that best suits your specific needs. In the next section, we’ll discuss how to deal with it.

Put on

How to measure the wear of a roller chain? There are several methods available, but the most accurate is to use a wear gauge kit. The CZPT Chain Wear Indicator Kit measures chain elongation. Compliant with ANSI and British Standards, this tool is critical to the industry chain and can help you determine when replacement is required. Improper chain maintenance can cause equipment to slip or perform poorly, resulting in unnecessary downtime.

In addition to measuring the elongation of the roller chain, it is also possible to measure the pitch of the rollers. This measurement represents the ANSI #80 standard for roller chains. Vernier calipers can also be used to measure the pitch of chains. This tool is very useful and also acts as a bottle opener. You can even use it as a wear gauge. This way, you can determine if the roller chain needs to be replaced.

The wear resistance of a roller chain can extend its life by 10% or more. However, proper lubrication and general maintenance are essential to ensure the longest lifespan of your chain. The manufacturing process of a roller chain assembly also plays a crucial role in determining its service life. For longer life, you might consider purchasing a heavy-duty series roller chain with thicker side plates and longer pins. If you need greater working load capacity, you can also consider heavy-duty chains.

High-quality components are critical to the longevity of the roller chain. High-quality roller chain components require precise heat treatment processes. The use of proprietary steel allows the company to manufacture more durable drums. The pins are manufactured to tight tolerances and then undergo a centerless grinding process. This process removes any surface defects, resulting in a mirror finish on the pins. The uniformity of this surface finish also ensures that the load is evenly distributed on the pins, extending the life of the chain.

Material

Among the materials used in roller chains, carbon steel and alloy steel are the most common. However, stainless steel is used in food processing equipment and applications that require lubrication. Other materials used for roller chains include nylon and brass. For more information, see the USACE Material Specification Sheet for more information. You can also find information about the performance of a roller chain by its design. But before choosing one of these materials, consider its pros and cons.

Stainless steel is an excellent choice for roller chains. It is corrosion-resistant and can operate in extreme temperatures without cracking. Stainless steel is a non-magnetic material that can operate in a temperature range of -200 degrees to +700 degrees Fahrenheit. In addition to its corrosion-resistant properties, stainless steel can withstand a variety of environments and can be used in heavy-duty applications. The MEGA series is the strongest stainless steel roller chain in the world.

Application

As the name suggests, a roller chain has 5 basic components: pins, bushings, rollers, and pin chainplates. These components are precision engineered to ensure optimum performance and durability. Typical applications include drives and conveyor belts. The various components of the roller chain can be customized to specific needs. Read on to learn more about how these parts work together. This article presents the advantages and disadvantages of different types of roller chains and discusses their applications.

A roller chain is a form of chain drive consisting of short cylindrical rollers connected together by side links and gears called sprockets. While these devices are simple, they have some limitations. In most cases, sprockets must be designed with a maximum tensile load on one tooth to prevent premature chain failure. Therefore, these chains are less efficient than belt drives with higher inertia.

Roller chains are usually made of carbon or alloy steel, although stainless steel is often used where food processing machinery and lubrication are problematic. Sometimes, nylon and brass are used. The maximum running speed of the roller chain is important for some applications, but it also provides economic benefits for users and manufacturers. The maximum running speed of a roller chain is usually governed by a wear limit, which can vary by application.

The global roller chain market is expected to grow at a CAGR of over 5.4% over the next six years. The research report covers the competitive landscape and key factors influencing the market. The report also analyzes the growth potential, product utilization, and pricing models of key vendors. It also covers the SWOT analysis of the key players in the industry. The study provides a comprehensive market analysis of all these factors and more. It also highlights key players and their strategies and identifies the fastest growing regions for their products and services.

Maintain

Because rollers are exposed to a variety of environments, including snow, rain, and muddy roads, regular maintenance is required to prevent damage. Because they must encounter these elements frequently, frequent inspections are important to prevent rust and other damage. Also, avoid pouring acidic or alkaline cleaning products on the roller chain. Instead, use hot water with hand sanitizer or a disposable toothbrush to clean the rollers. Washing the chain directly with water has little effect.

For small rollers, the workload during the break-in period should not be too large, otherwise, it will cause overheating. The small drum should also be inspected frequently for any unusual appearance, which may indicate that the system is not functioning properly. In this case, the operation must be suspended. Failure to do so could result in serious injury or a facility fire. Additionally, a properly lubricated roller chain is essential to ensure long-term performance.

The surface of the roller is often rusted and scratched. Over time, these little scars can spread to the drive, damaging it. Also, the chain may not be properly spaced and timed. Therefore, it is very important to check regularly to ensure that the chain is in top condition. When the chain wears to 3% or more, the entire roller chain needs to be replaced. Failure to do so may damage the drive, the roller sprocket, or the entire chain.

Given the chain’s processing environment, lubrication is critical to its performance. If the chain is lubricated, it must be re-lubricated frequently. However, lubricated roller chains are susceptible to contamination, especially in the biomass industry. In these environments, airborne organic particles and debris from the biomass industry can contaminate lubricated roller chains. This is why maintenance is important for lubricating roller chains.

Preloading

The benefits of preloading roller chains are well documented. In general, preloading eliminates the initial elongation of the roller chain, increasing its service life. Preloading is an effective way to achieve this, and a preloading chart can help illustrate the benefits of this process. Chains with little or no preload will stretch significantly during drive start, while chains will stretch rapidly as the surface hardness of the wear parts increases. Additionally, a properly preloaded chain has little or no elongation during the initial start-up of the drive, extending wear life.

Premium manufacturers apply the preload concept during their production phase, aligning all major components at the same time. This approach helps eliminate elongation issues that lead to rapid degradation of the roller chain. If this is not checked, the chain drive will stretch immediately over time. To avoid these problems, it is important to purchase a high-quality preloaded roller chain from a reputable source.

The heat treatment process is an effective way to prevent excessive wear of the roller chain. Heat treatment is a complex process that takes place in a factory during manufacturing. This process helps the rollers maintain high hardness and depth, preventing breakage. When buying a roller chain, make sure that the chain is heat treated and that the chain is manufactured to a high degree of precision. It also ensures that the product can be used for a long time.

In addition to performance benefits, preloading can also reduce initial elongation. A preloaded roller chain will exhibit near linear elongation, whereas a non-preloaded chain will experience rapid elongation. Therefore, they will reach the recommended 3% elongation earlier. Make sure the chain is properly lubricated. Also, consider how the chain is arranged. This is critical for optimal longevity.

editor by czh 2023-01-14

China Motor OEM Tangchen According to Design Concrete Mixer Machine Chain supplier

Merchandise Description

one. This device is employed to transfer upper mould transversely.

two. Control Technique: Electrical component demands to be connected to the energy of 380V/50Hz.

| Merchandise identify | specification |

| #2242 | duration 2242mm |

| #4222 | length 4222mm |

| #5212 | size 5212mm |

| #6202 | duration 6202mm |

| #3232 | size 3232mm |

* The duration of conveyor can be create according to design.

ZheJiang Tang Chen Machinery Equipments Manufacturing Co., Ltd. is Established in 2011 with registed capital of 25,000,000 CNY, masking a total region of thirteen.34 hectare such as 43000 square meter workshop.

The company mainly focuses on the R&D, generation and revenue of the CZPT & gear for precast concrete aspects, specifically for concrete spun pile and spun pole.

Instead of only supplying machinery, we supply built-in answer with worth included service, so that consumers can easily start manufacturing by just turning the key.

At present the business have exported to Korea, Vietnam, Malaysia, Bangladesh, Cambodia and Indonesia. And have efficiently built more than 10 abroad assignments.

We are self-confident we will always be the appropriate choice for you!

Tangchen can offer profecssional concrete creation line.

action 1 raw materials mixing & steel bar cage generating

stage 2 cage inserting & concrete feeding

action 3 stressing

phase 4 centrifugal spinning

action 4 steam curing

stage 5 demoulding

phase 6 high pressure curing

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Transport Machinery |

| Shotcrete Type: | OEM |

| Machining Process: | Processing, Welding, Paiting |

| Structure: | Electrical Motor |

###

| Customization: |

Available

|

|---|

###

| Product name | specification |

| #2242 | length 2242mm |

| #4222 | length 4222mm |

| #5212 | length 5212mm |

| #6202 | length 6202mm |

| #3232 | length 3232mm |

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Transport Machinery |

| Shotcrete Type: | OEM |

| Machining Process: | Processing, Welding, Paiting |

| Structure: | Electrical Motor |

###

| Customization: |

Available

|

|---|

###

| Product name | specification |

| #2242 | length 2242mm |

| #4222 | length 4222mm |

| #5212 | length 5212mm |

| #6202 | length 6202mm |

| #3232 | length 3232mm |

Different types of drive chains

There are many different types of drive chains. You should be able to differentiate between roller chains, forged rivetless chains, double chains, flat-top chains, and helical chains by the terms used. This article will provide information on the different types of chains. Then, you can choose the right one according to your needs. If you haven’t purchased a chain yet, read this article to get started. It will also provide information on the pros and cons of each type.

roller chain

There are several differences between drive chains and roller chains, but in essence, the two are functionally similar. The choice of which type to use depends largely on the type of environment it will be exposed to. While roller chains are suitable for clean indoor environments, they are not very forgiving when it comes to rubbing against the rails. Following are the main differences between a drive chain and a roller chain. Using the correct drive chain is essential for a smooth and efficient running machine.

Roller chain drive chains come in many different weights and tensile strengths. For light-duty applications, use a smaller pitch chain. For heavy-duty applications, use larger pitch chains. The design simplicity of these chains makes them ideal for a variety of applications. While they are great for a variety of applications, the durability of these chains makes them ideal for a variety of applications. Some of the main uses of roller chain drive chains are listed below.

When replacing the drive chain, be sure to follow the safety guidelines. The most important thing to remember is not to place the chain on a dirty floor as it may cause stretch or damage. After removing the chain from the sprocket, apply the measured load specified by ANSI to it. If the load exceeds this value, the chain may bend. A suitable load for measuring a drive chain should be at least six links.

While roller chains are usually made of carbon steel, some are made of stainless steel and are used in food processing machinery. In these environments, the chain may be made of stainless steel for lubrication. Brass and nylon are also sometimes used to meet these requirements. Regardless of the application, however, choosing the right drive chain is critical to the success of a roller chain machine. It is important to maintain the proper balance between the roller chain and the machine.

To properly use a roller chain, first determine the size of the sprocket used for the drive. The size of the chain should be smaller than the smallest sprocket to prevent tooth interference and provide adequate winding on the smaller sprocket. A good practice is to choose a drive chain with a center distance of 30 to 50 times the chain pitch. The longest possible center-to-center distance is approximately 80 times the chain pitch but is not recommended for high-speed applications.

Drop forged rivetless chain

Drop-forged rivetless drive chains are made of drop-forged steel components. Their proportions are suitable for strength and lightweight. Forged rivetless chains are generally divided into three types. Each of these types has its own set of important specifications. Key topics include minimum ultimate tensile strength, chain length tolerances, and link dimensions. Read on to learn more about each type and its uses.

One of the main features of forged rivetless chains is that, despite their relatively low price, they are designed to be very durable. The quality of a forged chain depends on the structure and design of the chain. The manufacturer of this type of drive chain is CZPT, which has a large stock of these chains. The chain is proof tested after assembly and comes with a two-year parts replacement warranty.

Forged rivetless chains are available in a variety of pitch sizes and strength grades. They are made of cast manganese or alloy steel and have an average strength of 24,000 to 300,000 pounds. These chains are suitable for automotive, conveyor, and material handling as well as meat packaging, sugar processing, and steel mill applications. They are also widely used in conveying systems. To ensure quality and performance, manufacturers offer a variety of forged chains.

CZPT offers forged CZPT drive chains for fatigue-free operation. The chain includes a solid one-piece forged drive pawl for optimum durability. Chains are available in Figure 8 and in D-shape styles. For more information, please contact CZPT directly. Custom Drop-Forged rivetless drive chains can be ordered. Manufacturers also offer custom chains for specific application needs.

double chain

Duplex drive chains have two sets of rollers instead of one, producing twice the power. Double chain roller chains have pins and roller bearings, while triple chain chains have an extra row of plates to accommodate the three sprockets. They are usually interchangeable with each other. They are available for US, UK, and ISO standards. They are made of carbon steel, stainless steel, and nickel or nickel-plated.

flat top chain

Flat-top drive chains are ideal for curved or straight tracks and come in many different types and thicknesses. These chains are highly resistant to wear and are usually made of steel, stainless steel, or plastic. CZPT manufactures special brands of flat-top chains with high wear resistance and excellent noise reduction. In addition to being versatile, flat-top chains can be used in a variety of industrial applications.

There are two main types of CZPT chains: solid top or raised rib. One piece is formed from a single unit link and the other has roller base links for added strength. The two-piece chain combines flat tabletop links and a roller bottom chain for added strength. These chains are available in widths up to 20 feet and are available in a variety of widths. These chains are available in stainless steel, cast iron, or plastic.

The hinge pin is another important part of the flat top chain system. Support chain plate to ensure smooth conveying. The hinges are available in single hinge pin and double hinge pin styles. Standard hinge pins are designed for straight, narrow-width chainplates; double hinge pins are designed for longer, heavier products. The hinge pins also come in many different materials, including aluminum and galvanized steel. This allows for customization based on machine design, operating conditions, and drive method.

Whether your flat-top chain conveyor system is large or small, a high-quality flat-top chain will get the job done. With their low maintenance and low maintenance design, these chains are easy to clean and maintain. They can accommodate workpiece pallets of various sizes, and their flexibility makes them ideal for many different applications. They can also be highly customized for various industries. So if you need an industry-specific conveyor, then a flat-top drive chain is the way to go.

editor by czh 2022-12-16

Stainless Steel Roller Chain 06b From China for Mask Making Machine

stainless metal roller chain 06B from China for mask generating equipment

Technical specs

|

Method Treatment |

|||

|

one |

Shot Peening |

eight |

Quenching |

|

2 |

Bluing |

9 |

Tempering |

|

3 |

Phosphate |

10 |

Oiling |

|

four |

Nickel-plated |

eleven |

Greasing |

|

5 |

Zincing |

twelve |

Special colour |

|

6 |

Warmth Remedy |

thirteen |

Stain proofing |

|

seven |

Carburizing |

fourteen |

Pre-stretched and anti-tiredness |

Make contact with details:

Packege and delivery

| Deal | one)Neutral deal + carton deal two)Carton package deal + pallet 3)Wood deal + pallet |

| Delivery Time | one-3 days after order |

| Shipping | by air to door deal with / by sea to sea port |

Firm Info

HangCZPT CZPT CZPT Co., Ltd. is specialised in bearings export production selling and soon after-services.

In practice for several several years, we set up rigid top quality assurance technique.

Our merchandise handles Roller CZPT, Ball CZPT, CZPT bearing, Rod conclude bearing, Joint bearing, Stainless Steel CZPTs, Ceramic bearings, CZPT bearing, Slender wall bearing, Excavator bearing, and Rotor bearing.

We do brand names:NSK NTN KOYO NACHI ASAHI IKO THK UBC NMB and DPI.

We do OEM service

Dwin made in China – replacement parts – in Astana Kazakhstan Transon Marble Granite Tombstone Head Granite Stone Laser Engraving Machine for Sale with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For a lot more information: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Merchandise Description

Dwin transon marble/granite /tombstone/head granite stone laser engraving equipment for sale

one.A few axles adopt import linear orbit,two line sliding observe,heavy loading,stable functioning ,large precision,long life span.

two.Whole seamless weld steel framework, not straightforward to distort, the desk back lining is armor plate,very good rigidity,the device can bear 1MT weight at minimum.

three. EPT compatibility,appropriate software program CAD/CAM,this sort of as Type 3.Artcam,Castmate,Wentai,Coreldraw.

4.Double route cutters cooling technique can lengthen the life time of utilizing .

| Model | DW9015 | DW1218 | DW1224 |

| X,Y Doing work location | 900*1500mm | 1200*1800mm | 1200*2400mm |

| Z Working spot | 250mm | 250mm | 250mm |

| Table dimensions | 1100mm*2000mm | 1400mm*2300mm | 1400mm*2900mm |

| Processing precision | 0.05mm granite stone laser engraving machine | ||

| Resolution precision | 0.02mm | ||

| X,Y construction | Rack equipment | ||

| Z construction | Ball screw | ||

| Command | G CODE | ||

| Max idle pace | 30m/min | ||

| Max engraving pace | 5m/min | ||

| Working voltage | AC380V/50Hz | ||

| Spindle rotating speed | -24000rpm/min | -24000rpm/min | -24000rpm/min |

| Generate motor | Steper(Selection:Servo) | ||

| Operation program | DPS/WEHINOG/MACH3 | ||

| Spindle power | 3KW/4.5KW/5.5KW/6KW/8KW | ||

Product Photos

Sample Drawing:

Packaging & Shipping

Company Info

HangZhou Dwin Technology Co., Ltd.Is a high-tech enterprise that is engaged in the investigation, manufacture

And sale of laser machines, laser engraving and cutting device, laser marking device ,CNC routers and

Pertinent advertisement goods.Dwin has acquired CE, Food and drug administration and ISO certifications.Our organization has

Effectively made DW series of products which appreciate a good reputation. EPT high quality and fa EPT support

Make our goods spread above Europe, The usa, the Center Ea EPT and Southea EPT Asia.

Dwin mainly creates laser engraving devices, laser reducing machines, laser marking devices,

Advertisement CNC routers, marble CNC routers and CNC woodworking machines.

Dwin equipment are broadly utilised in garment cutting, craftwork, rubber plate, package deal printing, leather-based slicing,

Sign marking, wood household furniture, development, decoration, stone engraving and mould making.Dwin CNC devices have tremendously improved the performance of relevant industries and the top quality of pertinent products.Dwin continuously

Pursues the philosophy of “complex innovation, cooperation and all win”, jointly with you for a brilliant potential.

We are sincerely searching forward to ongoing instruction and help from our clientele.

Our Services

| Coaching: One particular technician will be assigned to client organization for 3 working days on totally free of demand fundamental. Customer is responsible for lodging, foodstuff and air tickets. |

| Remark: 1.Installation guide and handbook and resource package will be despatched to Purchaser with device. two.All spare parts on equipment we take use high good quality and skilled set up. 3.Machine has been tested for 72 hours without quit prior to supply. 4.CE ,Fda licensed , ISO9001 Dwin strictly carried out. |

| Ensure & After Income Service: one.18months good quality guaranty, the device with principal components (excluding the consumables) shall be Transformed cost-free of demand when problems occurred throughout the warranty period. two.Life time routine maintenance free of charge. three.Free of charge training program at our plant. 4.We will provide the consumable areas at an company price tag when you need replacement. five.24 hrs on line provider every single working day, free of charge technological assist. |

The Exhibition

Certificate

Contact Information:

The use of first products manufacturer’s (OEM) element numbers or logos , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our business and the outlined substitute components contained herein are not sponsored, accredited, or created by the OEM.

Plastic Custom made in China – replacement parts – in Hai Phong Viet Nam Silica Gel Automatic Liquid Color Spray Coating Production Machine with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing unit in China with 5 various branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Welcome to Guanjie, and we are the manufacturing facility to produce the Liquid Painting Line, Powder Coating Line and Logistics Transport Line.

All tools is custom-made for your solution necessity.

Merchandise Imformation

Principal Techniques Such as:

| Systems | Technological Approach and Possibilities |

| Pretreatment | Washing, degreasing, etching, phosphating, blasting |

| Spray Booths | Guide or automated with powder recycle system |

| Drying&Curing Ovens | Tunnel ovens, bridge ovens |

| Heating Resource | Coal/diesel/bio-particles/L.P.G./N.G./electric power |

| Transportation method | Chain conveyor, power and free of charge conveyor |

H2o spray paint area

The outside air after purification filter substance spray chamber prime into the spray chamber from the leading down through the workpiece all around and staff, and then for ventilation result outdoor exhau EPT fan will function in creating made up of particles quickly induced drinking water whirling device to the floor grid under, from the h2o overflow overflow to disk the water whirling device in the drinking water at high speed below the motion of the airflow is atomized and into the air the h2o whirling unit within the nicely blended, will clean the greater part of particles which into the drinking water.

The dip collection and curing program

Dip sequence advantages:

Dip from the preheating furnace generation line, automatic dip powder system, vibration tools,plastics furnace products transportation gear. Electronic handle gadgets, is appropriate for EPT Bing cupboard mesh, fence, fences.security windows, stencil coating.

Curing Sequence Characteristics:

The organization is a kind of curing oven drying range: a straight-via, total bridge, 50 percent bridge, and EPT means, by heating in groups A, with fuel (fuel) heating bellows ring. Centralized heating sizzling air circulation way, considerably infrared heating scorching air stirring technique, coal heating, for distinct users

and situations.

Conveying method and electric manage program

Suspension conveyor chain is carrying a conveyor is operating in the keep track of of the rack and the pulley on the chain, and working in the index tracks.

Technological Process

Benefit

Our automated portray line is taken care of with chain conveyor to send items by way of preset treatment phases (electrostatic cleansing, paint booth and dry oven and many others). Flow chart can be customized in accordance to distinct solution treatment method requirements this kind of as electrostatic coating, DI EPT coating, PU or drinking water based mostly coating and so forth.

Product Categories

Organization method diagram

Contact us

We are located in the forefront of China’s reform and opening up town -HangZhou, is a set style, improvement, manufacture, set up and debugging, technological education, and perfect pre-market soon after-product sales service in the integration of industrial automation coating gear professional makers. Much experience in powder coating tools, we can provide you with modern, rational and economical remedies. We can assistance you with superior systems.

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original tools manufacturer’s (OEM) element numbers or emblems , e.g. CASE® and John Deere® are for reference functions only and for indicating item use and compatibility. Our business and the outlined substitution elements contained herein are not sponsored, accredited, or made by the OEM.

1325 made in China – replacement parts – in Tashkent Uzbekistan CNC Router Machine for Aluminum with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 distinct branches. For more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

1325 CNC Router Equipment for Aluminum

Characteristic:

1. Ball screw for Z axis.It is steady operating,precision and fast.

2. X,Y axis are gear rack,regular charge transmission,fa EPT speed and substantial efficiency.

3. With NC controller method,simple to discover design and style application,ju EPT install it on to your organization and commence producing styles.

4. Hefty responsibility frame and grantry,quite strong and steadiness.

Parameter:

|

Parameters |

Standard Specifications |

|

X,Y,Z Working Area |

1300*2500*200mm |

|

Spindle |

3kw water cooling spindle |

|

X,Y,Z Traveling Positioning Accuracy |

±0.01/2000mm |

|

Table |

Vacuum table or T-slot desk |

|

X,Y,Z Rail and Transmission |

ZheJiang TBI Ball Screw and Gear rack |

|

Max. Rapid Travel Rate |

50000mm/min |

|

Max. Working Speed |

30000mm/min |

|

Spindle Speed |

24000RPM |

|

Drive Motors |

Stepper motor |

|

Working Voltage |

AC380V/3PH/50Hz or 220V |

|

Command Language |

G Code |

|

Control System |

NC Studio or DSP/Mach3/Syntec |

|

Software |

Alternative:Type3, Ucancam, Artcam, solidworks,and so forth. |

|

Running Environment |

Temperature: 0ºC~45ºC Relative Humidity: 30%~seventy five% |

|

Frame structure |

Welding structure |

Application:

one) Mould: wooden,wax, wooden, gypsum,foams,wax.

two) Furniture: wood doors, cupboards, plate, office and wooden furnishings, tables, chair, doors and windows.

three) The wooden goods: voice box, sport cabinets, personal computer tables, stitching devices table,instruments.

four) Plate processing: insulation component, plastic chemical components, PCB, internal body of vehicle, bowling tracks, stairs, anti bate board, epoxy resin, Abdominal muscles, PP, PE and EPT carbon combined compounds.

5) Beautify industry: Acrylic, PVC, MDF, synthetic stone, organic and natural glass, plastic and gentle meta EPT such as copper, aluminum plate engraving and milling procedure.

Deal and Shipping and delivery:

Bundle Detail:1)Exterior package deal:Normal plywood package.

2)Internal deal:Stretchy film and plastic movie for humidity.

And we can deal according yo your requests.

Delivery Depth:For standard equipment,it will be 7-15 doing work days after payment:For non-regular equipment and customized machines according to clients’ specific requirements,it will be twenty-30 functioning days after payment.

Right after Sale Support:

- Engineers accessible to service machinery overseas.

- one year promise for total device.

- Technological help by telephone,e-mail,whatsapp and skype.If you have any issues,we will inside of 12 several hours to resolve it.

- You will be get free coaching guidance toward our device in our manufacturing unit.

- If you need any component of the machine,we will offer the be EPT value for you.

- Friendly English version guide and procedure video CD disk.

Business Information:

Artech is comprehensive in the generation, design and style, production, trade and support of CNC machine, and supply high high quality and excellent efficient CNC devices around the world. With a sturdy personnel staff, “Brand name ArtechCNC” gained achievement in woodworking engraving equipment, marketing engraving machine, stone engraving machine, steel engraving equipment, laser engraving machine and laser cutting sector equipment. The manufacturing amenities occupies China’s forefront in development and growth.

FAQ:

Q1 For offer you the mo EPT suited device,how ought to i do?

- The precise materia EPT you want to engraver/cut?(such as wood,acrylic,fabric,fabric,leather-based,metallic…?)

- For the spindle electricity,might i know the cutting or engraving depth you want?

- The doing work area you need?(this kind of as max dimension of resources,width*length,1200*1200mm,1300*2500mm,2000*3000mm,and so on)

- Do you want to engrave on planar&flat surface area or round&curved floor?

If sure,the equipment shall be included optional objects,this kind of as rotary attachment.If you can offer some photographs of your merchandise,that would be wonderful!Soon after you explain to us these,we will deliver you much more details about the device and price.

Q2.If we do not know how to use the machine,you can teach us?

Of course,we will,if you come to China,we will offer you you totally free instruction until you can use machine freely.And if you are occupied,we will have the specific engineer to your place,but you require bear some fee,like tickets and hotel and metallic.

Q3.How about your soon after-sale service?

We offer you you 24 hours services phone,skype,whatsapp and email.

Q4.How about your assure interval?

1 year and for the duration of the time,if you have any inquiries,we will fix it for cost-free.

Buyers Function:

Customer’s Suggestions:

The use of authentic products manufacturer’s (OEM) element quantities or trademarks , e.g. CASE® and John Deere® are for reference functions only and for indicating merchandise use and compatibility. Our business and the shown replacement elements contained herein are not sponsored, accepted, or produced by the OEM.

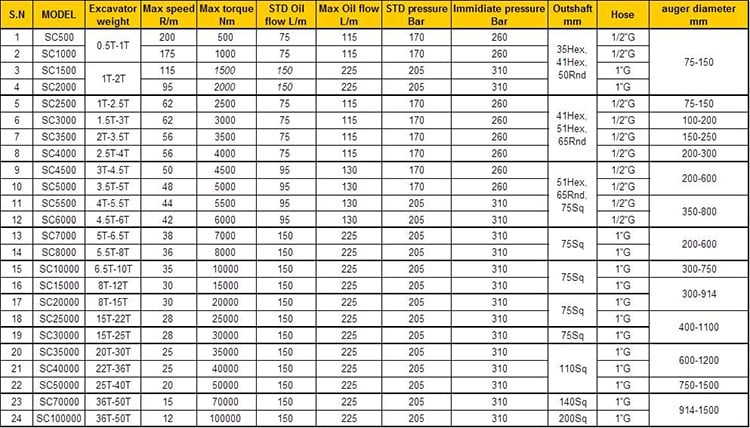

China manufacturer & factory supplier for high in Penza Russian Federation speed Earth Auger Drilling machine For Excavator Used With high quality best price & service

ISO 9001 accredited producer of precision roller chains. Kinds contain solitary and numerous strand, hollow pin, facet bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains.The new goods incorporate a collection of substantial-tech and high high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, large-velocity tooth chains, timing chains, self-lubrication chains, among which have type higher pace tooth chain for vehicle department dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Rapid Particulars

- Problem:

-

New

- Guarantee:

-

1.5 years

- Relevant Industries:

-

Manufacturing Plant

- After Warranty Services:

-

Movie specialized assist

- Local Service Location:

-

None

- Showroom Area:

-

United States

- Variety:

-

Bearing

- Use:

-

Cultivators

- Spot of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Neighborhood Support Spot:

-

United States

- Software:

-

dig hole, tree planting, solar project

- issue:

-

new

- Ideal:

-

one-50 ton excavator,crane ,skid steer loader

- auger diameter:

-

75-1500mm

- Depth:

-

20M

- STD oil stream:

-

75L/M

- STD pressure:

-

a hundred and seventy bar

- outshaft:

-

41/51HEX, 65 Rnd,75Squ

- Shade:

-

blue or black

Supply Capability

- Supply Capacity:

- one thousand Set/Sets for every Thirty day period

Packaging & Supply

- Packaging Specifics

- BOX

- Port

- QINGDAO,DALIAN, SHANGHAI, NINGBO

On the web Customization

Our factory has acquired the certification of China’s Farm Equipment Merchandise High quality Authentication promulgated by the Farm Machinery Items Good quality Authentication Centre of China.

high speed Earth Auger Drilling device For Excavator Utilized

Item Description

Earth Drills are renowned during the globe for being the greatest augur method accessible. A big variety of types are accessible to fit any device and hole unexciting process from the smallest fencing work through to key piling operates. With a revolutionary gearbox and non-dislodgement shaft, the EPG Earth Drill is developed to out-execute and outlast, turning your equipment into a genuinely universal piece of products.

Why we choose this earth auger?

It is obviously that earth auger is more efficient than manual work. Besides, using our product is safer than manual work. The hole which dig by the earth auger is more beautiful than man did.

Characteristics & Rewards

– Non-dislodgment shaft.

– Epicyclic Gearbox

– Hose & Coupler alternatives

– High top quality hydraulic motor

– Forged hood ears

– Shock-lock tooth locking technique

– Augers from 75mm to 1200mm

– new earth drills

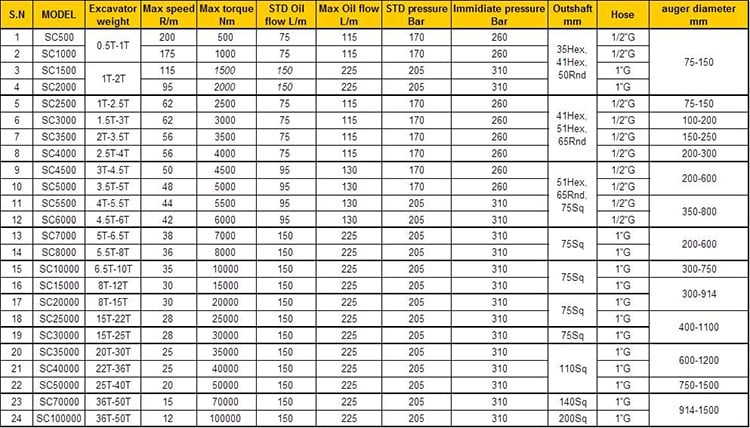

Specification

Auger Push

1.Forged hoods ears: Deal with the heavy strain of daily use. Contact surface wider and safer.

2.American Motor: Developing the most reliable wear parts.

three.ERICYLIC gearbox: Unique planetary gearbox. Multiplied output torque. Extreme efficiency.

4.NON-dislodgement shaft: Assembled top down locked into earth drill house. Never fall out. Provided a safer environment.

5.18 Month After-sales service for auger drive.

earth auger for excavator used Earth Auger Drill For Excavator Earth Drill Auger For Excavator

How to choose the most suitable type?

Relevant spare elements

Our auger teeth have patented unique design.Different teeth for different earth condition.

With those, I believe it is no problem to dig your dream hole.

a lot more auger photographs

Manufacturing facility & Packaging

FAQ

Q: HOW CAN I Choose THE Suited EARTH DRILL?

A:Remember to REFER TO Underneath Concerns:

- 1. Model and model of Excavator/Backhoe/Skid Steer loader?

- 2. Diameter of gap to be drilled?

- three. This way of working produces synergies amongst the diverse items if we incorporate a quite dynamic and expert policy, the end result is a large profitability in strategic discounts, that warrants the reward of our consumers. Depth of gap to be drilled?

- four. Ground kind to be drilled?

Once you have answered the earlier mentioned you can very easily make the correct option.

Q: DO I NEEDIn our firm we are conscious of the importance of the users’ safety. That’s why our PTO’s are made in accordance to authorized rules and European directives and bear the CE indication. A key element for safety assurance is the accession in the products’ advancement section. By all indicates, the users’ understanding about the right use of a PTO drive shaft is essential. This indicates, that each and every users’ obligation is to read and follow the protection guidelines. TO Buy SPARE Areas WHEN Buying AN EARTH DRILL?

A: It is not needed to acquire spare areas for the Planetary Travel as this is a sealed unit, however it is essential to adhere to the support routine as outlined in the operators handbook. It is recommended to purchase spare putting on areas (teeth and Pilots).

Q: CAN THE EARTH DRILL Fit A Assortment OF Machines?

A: Of course, as extended as the carrier’s technical specs agree with the parameters of the Earth Drill as outlined in our catalogue.

Q: HOW DO I Fit THE EARTH DRILL TO MY Equipment?

A: There are four sorts of mounting linkage offered

- Double Pin Hitch: to be used with excavators equipped with quick couplers.

- Double Pin Cradle hitch: also to be employed with excavators fitted with swift hitch, in addition the Cradle hitch can be used to stabilise the Earth Drill although travelling close to the website and also to aid in the clearing of spoil from the auger.

Q: WHAT CAN I DRILL?

A: There are 3 sorts of cutting tooth accessible,

1.Earth and Clay Tooth: Appropriate for drilling earth and clay.

2.Tungsten Teeth: Suitable for drilling challenging and abrasive floor.

three.Rock Enamel: Appropriate for drilling gentle, fractured, rock.

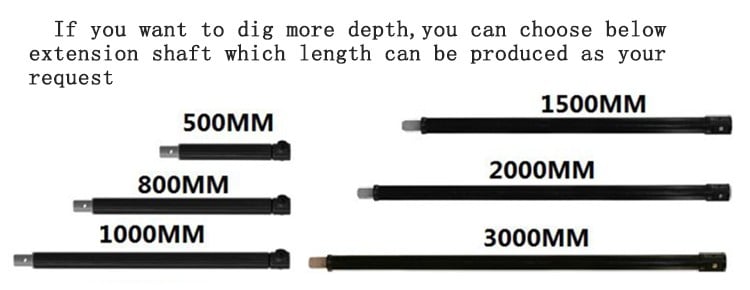

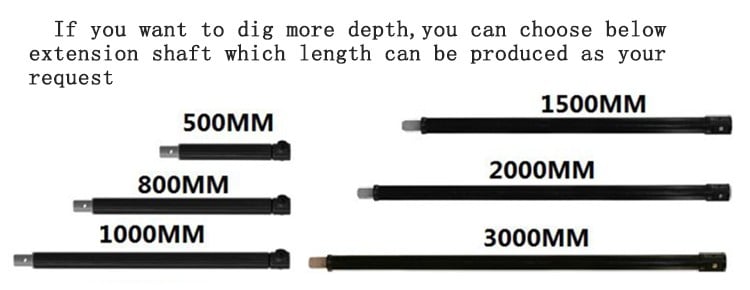

Q: HOW DEEP CAN I DRILL?

A: There are extensions accessible for every single Earth Drill however greatest drilling depth rely on the following problems

- Diameter of hole to be drilled

- Depth of gap to be drilled

- Kind of mother or father equipment to be utilised

- Ground kind to be drilled

Other attachments

Steel made in China – replacement parts – in Daegu Republic of Korea Spur Transmission Bevel Gear for Conveyor, Planetary Transmission Gear for Machine with ce certificate top quality low price

We – EPG Group the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 various branches. For more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Advantages&colon

one&time period Expert gears manufacturer

two&periodExperienced in Cooperate with massive Companies

three&interval Specialist gears EPT Ability

4&periodStable gears Top quality

five&periodReasonable gears Prices

six&periodSmall gears Orders Accepted

7&periodContinuous gears good quality advancements

eight&period of time Higher gears quality Functionality

nine&periodShort gears lead time and cargo

ten&periodProfessional gears support

We can provide with sample for top quality and operate tests&time period

Product Description&colon

| Material | Carbon Metal | SAE1571&comma SAE1045&comma Cr12&comma 40Cr&comma Y15Pb&comma 1214Letc | |

| Alloy Stee | 20CrMnTi&comma 16MnCr5&comma 20CrMnMo&comma 41CrMo&comma 17CrNiMo5etc | ||

| Brass&solBronze | HPb59-1&comma H70&comma CuZn39Pb2&comma CuZn40Pb2&comma C38000&comma CuZn40etc | ||

| Sort | Bevel Gear | ||

| Treatment | Heat therapies&comma Carburizing&comma Sprucing | ||

| Standard | ISO &solR 606 | ||

| Machining procedure | fabrication&commastamping&commadeep drawing&commagear hobbing&comma gear milling&comma gear shaping&comma machining and assembly gear broaching&comma gear grinding and gear gaping | ||

| Module | 1&period0&comma 1&period25&comma 1&period5&comma 1&period75&comma 2&period0&comma 2&period25&comma 2&period5&period&period&time period&period8&period0 and so forth | ||

| Tolerance control | Outer Diameter&colon&pm0&period005mm | Size Dimension&colon&pm0&period05 mm | |

| Enamel accuracy | GB1244-85&comma DIN8188&comma ISO&solR 606 &comma ANSI B 29&period1M | ||

| Heat remedy | Quenching & Tempering&comma Carburizing & Quenching&comma High-frequency Hardening&comma Carbonitriding&period&period of time&interval | ||

| Surface treatment | Blacking&comma Polishing&comma Anodization&comma Chrome plating&comma Zinc plating&comma Nickel plating&time period&period&interval | ||

Our business has a variety of imported substantial-precision processing gear&comma sophisticated generation technologies &commaimprove the signifies of detection&comma a sound merchandise quality administration program&comma for customers ca EPT first-course high quality &time period

Our Support

one&periodOEM&colon In accordance to your drawings and samples specifications&period

two&periodManufacturer with competitive price and high high quality&period of time

3&time period 100&percnt inspection before supply&period of time

four&time period Practical transportation&period

5&period Good packing&interval

six&period Small gears Orders Recognized&period

seven&time period Wealthy seasoned staff Professional complex support and resolution staff

Packaging & Delivery&colon

Packaging Information&colon Plastic bag internal and standard carton outer or as per client’s demands

Supply Depth&colon Transported in 20-30 days after advance TT payment

If there are any queries or require our support&comma you should speak to with us with no hesitate &comma or you can ship a message to us &period of time

The use of unique equipment manufacturer’s (OEM) portion figures or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our firm and the detailed substitution parts contained herein are not sponsored, accredited, or created by the OEM.